Constructing the largest civil works project ever undertaken by the U.S. Army Corps of Engineers

Market

Civil & Marine

Key Services

Construction

Preconstruction

Self-Perform

Steel Fabrication

Strategic Partnerships

Delivery Method

General Contracting (GC)Self Perform %

95Work Hours

13,700,000The challenge

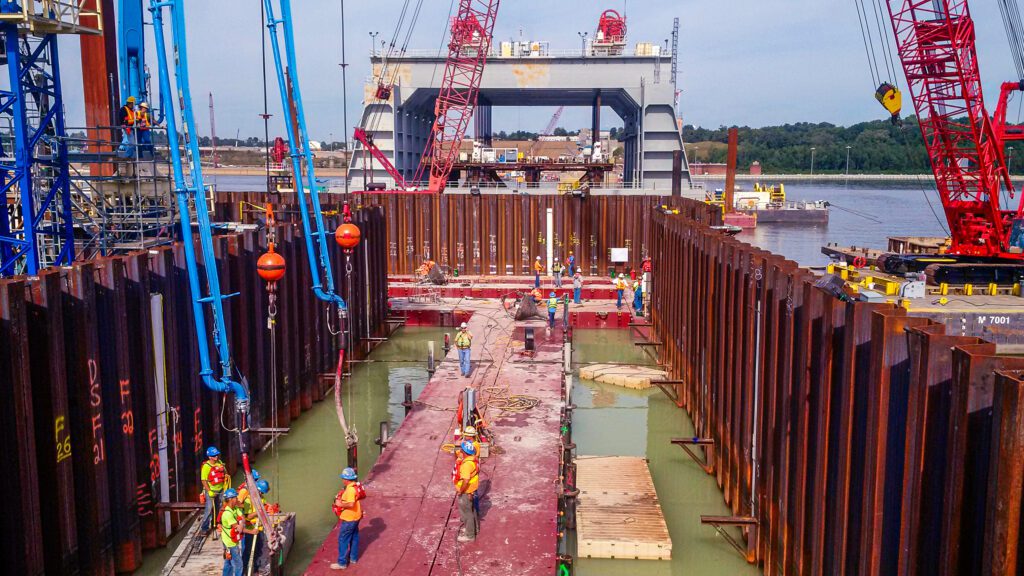

Construction of the $2 billion Olmsted Dam, located at a point on the Ohio River where more annual commercial tonnage passes than any other in the country, posed several significant challenges. The project required installing massive tainter gates and wicket gates, as well as a fixed weir, to improve navigation and safety on the busy inland waterway. The sheer size and weight of the precast concrete shells, reaching up to nearly 5,000 tons, made transportation and placement a complex task. Additionally, construction needed to minimize disruptions to existing river traffic and the environment while ensuring the safety of the workforce.

Key Facts

U.S. Army Corps of Engineers HQ Innovation of the Year Award

“Star” certification from the OSHA Voluntary Protection Program

2,596-foot-wide dam

55 precast concrete shells

23 million tons of rebar

Challenge met

To tackle these challenges, Alberici employed innovative construction techniques. The “in-the-wet” method eliminated the need for traditional cofferdams, reducing environmental impacts and maintaining river traffic flow. The team utilized specialized equipment, including a 5,300-ton gantry crane and a unique “aqua-digger” excavator barge capable of working in 80 feet of water, to efficiently handle heavy lifting and precise placement of the concrete shells. The use of high-tech sonar, video-imaging, and real-time kinetic GPS ensured accurate placement of the shells on the underwater foundation.

Alberici’s commitment to safety and quality earned the project “Star” certification from the OSHA Voluntary Protection Program, a prestigious recognition for safety excellence. The successful completion of the Olmsted Dam project not only improved navigation and safety on the Ohio River but also showcased Alberici’s expertise in managing large-scale and complex civil works projects.