Multiple expansions and process equipment installations while maintaining 24/7 operations

Market

Food & Beverage

Key Services

Construction

Preconstruction

Delivery Method

Design-Build (DB)Capacity

10,000 SF meat processing area, 9,000 SF administrative offices, 8,800 SF can operations production area, 6,600 SF warehouse additionThe challenge

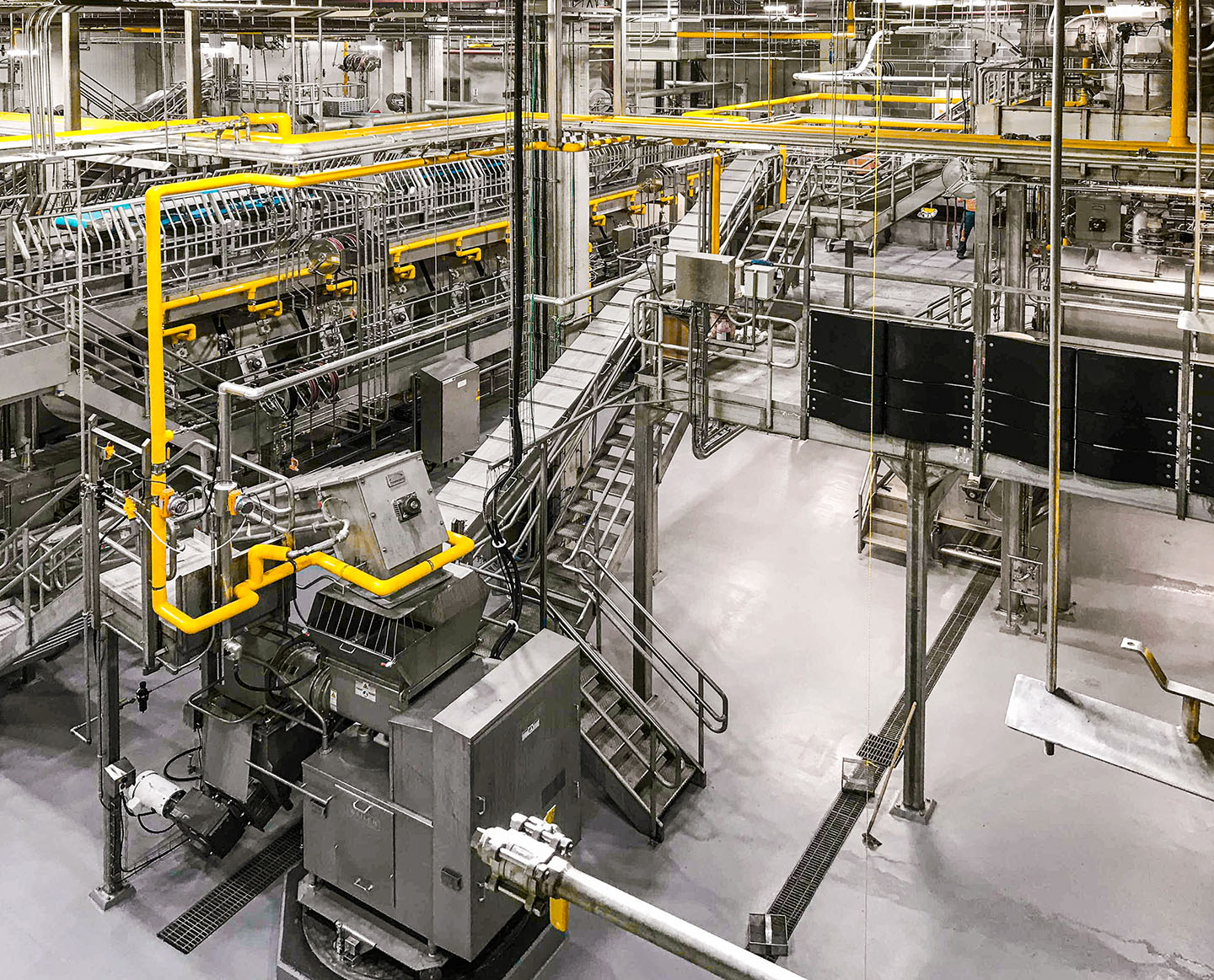

The Nestlé Purina Petcare Allentown Production Facility Expansion presented a significant challenge for Alberici as they needed to meet the growing demand in the pet food industry while ensuring the operational continuity of the existing production facility. The challenge involved performing extensive renovations and additions within an operational plant to accommodate new automated processing systems, all while adhering to Nestlé Purina’s stringent safety and food sanitation standards. Additionally, the project had to be completed within a tight timeline of less than 24 months.

Key Facts

24-month schedule

Multiple building expansions

Maintained plant operations

Challenge met

Alberici executed the Allentown Production Facility Expansion using design-build delivery, achieving success within a demanding 24-month timeline. The comprehensive solution included constructing a 10,000-square-foot processing area, an 8,800-square-foot canning operations expansion, and a 6,600-square-foot packaging building, along with utility system upgrades. They ensured minimal disruption to Nestlé Purina Petcare’s around-the-clock production schedule by employing phasing strategies and FDA-approved temporary partition walls. Alberici also installed temporary exhaust systems to prevent fumes from interfering with production until permanent HVAC systems were ready. The project’s successful completion emphasized their commitment to quality and highlighted their capacity to deliver complex projects. This marked the third successful capital improvement project for Nestlé Purina Petcare in six years, showcasing a strong and effective partnership.