Market

Automotive

Key Services

Construction

Preconstruction

Self-Perform

Steel Fabrication

Strategic Partnerships

Virtual Design & Construction

Delivery Method

Construction Manager at Risk (CMAR)Capacity

100,000 SFThe challenge

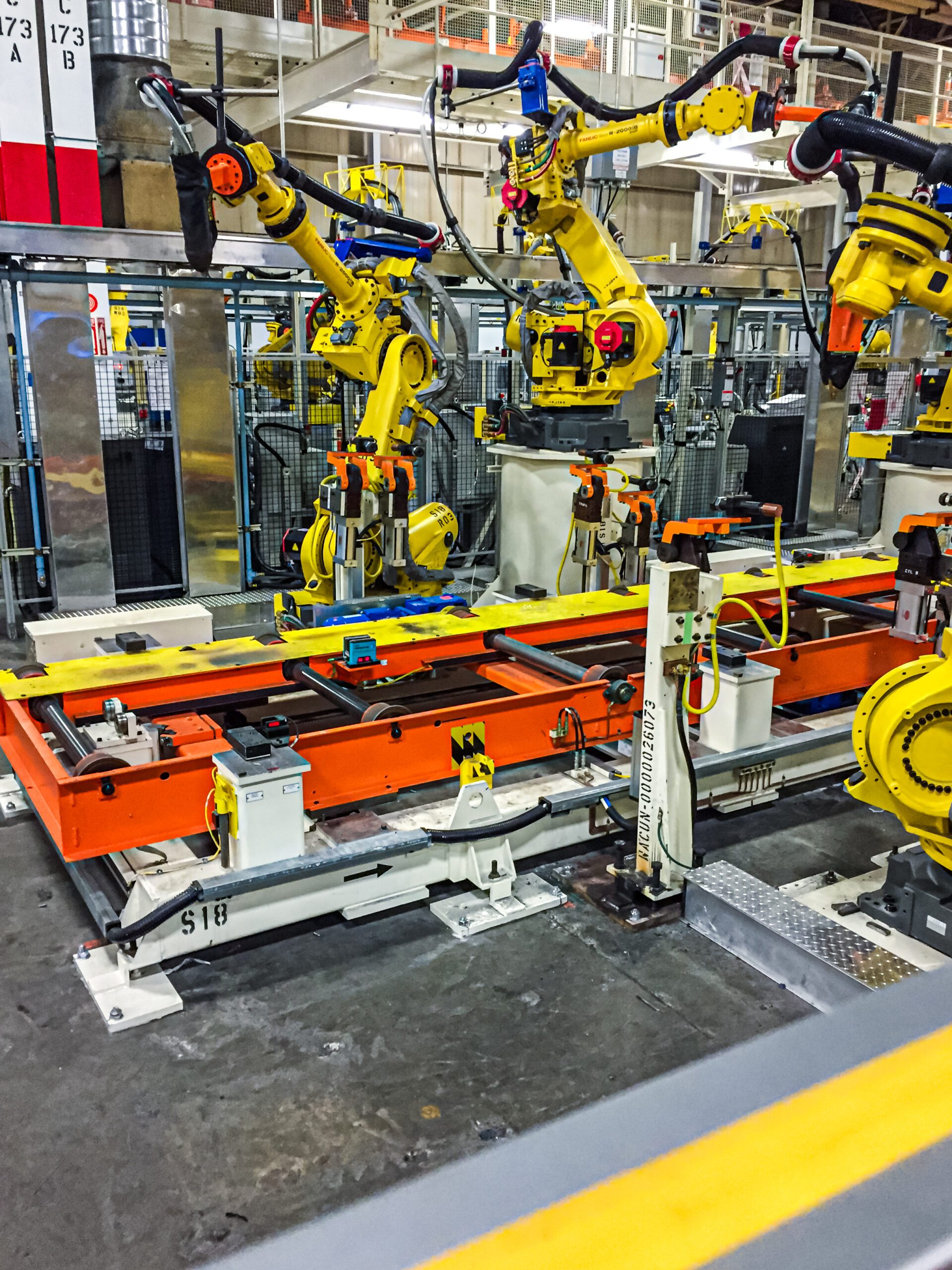

The main challenge faced by Alberici during the major renovations at the Stellantis Windsor assembly plant was to deliver extensive improvements in preparation for the launch of the new Chrysler Pacifica. The project required significant changes to the facility to support the new RU platform, including the installation of advanced robotics, miles of new process systems, and the execution of both the body-in-white and general assembly installation packages. With an aggressive and rigid 14-week schedule, Alberici needed to ensure that critical launch deadlines were met to support Stellantis’ production plans for the new minivan.

Key Facts

121 systems modified

14-week shutdown

Completed 30 days ahead of schedule

Challenge met

Alberici pooled global resources and implemented an efficient, collaborative approach to meet the challenge in automotive construction. Engaging field supervision and equipment

from multiple operating companies, we led a workforce of 1,200, ensuring effective project execution.

Detailed planning and sequencing accelerated the schedule, with strategic coordination of activities like equipment demolition, robot installation, and conveyance-header steel setting.

Self-performing the design, fabrication, and installation of the water test booth showcased our precision capabilities. While prioritizing safety and quality, Alberici completed the project an entire month ahead of schedule, allowing Stellantis ample time for a successful Chrysler Pacifica minivan production launch.

By delivering extraordinary results through strategic planning, resource coordination, and meticulous execution, Alberici showcased our commitment to excellence, timeliness, safety

and high-quality automotive manufacturing.