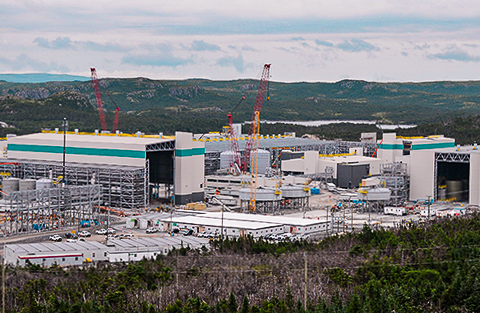

Building one of the largest, most technologically advanced nickel processing plants in the world

Market

Heavy Industrial

Key Services

Construction

Self-Perform

Delivery Method

General Contracting (GC)Self Perform %

67Capacity

Nickel/Cobalt Electrowinning Building – 263,000 SF; Neutralization Building – 182,000 SFWork Hours

6MThe challenge

Constructing Vale’s innovative processing plant in Newfoundland and Labrador presented a unique set of challenges. The massive facility features innovative hydrometallurgical processes that refine and ship 50,000 tons of nickel ore per year in a more economical and environmentally friendly manner. The remote location, complex hydrometallurgical processes, and need to adhere to high environmental standards required meticulous planning and execution.

Key Facts

21,200 tons of steel erected

60 miles of electrical cable installed

3,200 craft workers on site during peak construction

Challenge met

To overcome the challenges of constructing Vale’s advanced processing plant, Alberici adopted a strategic approach. We successfully managed multiple contracts for constructing specialized buildings within the 800,000 SF process area, including steel module erection and extensive mechanical and electrical work. We efficiently assembled, installed, and commissioned plant equipment, ensuring seamless functionality. To support Vale’s local commitment, Alberici prioritized local subcontractors and workers, employing a largely regional craft workforce that peaked at 3,200. With safety as a top priority, the project involved more than 6 million work hours without incident. Through careful planning, technical expertise, and collaborative efforts, we completed the complex project, contributing to Vale’s ecologically responsible and economically beneficial nickel ore processing, while bolstering the Long Harbour community’s growth and development.